04 February 2024 //

Shrink Bundling SystemsFlexible Packaging

Why Shrink Wrap Packaging Could Be The Best Application For Your Packaging Process

Finding dependable packaging solutions is crucial if you’re a business that sells consumer-shipped products. Your team must ensure products stay protected and secure as they ship to customers — the right material leaves recipients satisfied and reduces replacement costs. But with all the materials available, it can be tricky to find the best one for your needs. Shrink wrap packaging is a popular option for many industries. From small personal care products to large windows and everything in between, shrink wrap can securely protect products as they travel to their destinations. It’s a protective and cost-effective option for many products and companies.

Here are more advantages of shrink wrapping and when it can be the best choice for your business.

5 Benefits of Shrink Wrap

Shrink wrap consists of polymer plastic film. Once you apply heat, it shrinks tightly over what it covers. Heat is applied to the film as it travels through a shrink tunnel hood. It wraps over and around a product to keep it tightly secure during shipping and handling.

1. High Protection Levels

Once you apply heat to a web of shrink wrap, it creates an extremely tight enclosure. The wrapping tightly covers the product inside and protects it from external elements like:

- Dust

- Dirt

- Weather-related elements

Because the heat shrink wrap fits around a product, it can fit items of many shapes and sizes and hold them in place. Some types of shrink packaging even protect from ultraviolet (UV) rays. This high-quality protection allows products to stay safe while being shipped worldwide. Overall, shrink wrapping provides exceptionally high protection levels for various products and companies.

2. Durability

Shrink wrap consists of extremely durable fibers and long-chain polymers. Shrink film can are available in a variety of materials. One particular example is low-density polyethylene (LDPE). LDPE is simple to make and highly sturdy. Despite being lightweight, it’s tough, making it ideal for packaging solutions, LDPE properties remain constant across a wide temperature range (-30F to 120F).

LDPE plastics, including industrial shrink wrap and plastic shrink variants, ensure the durability and robustness of shrink wrap packaging. LDPE plastics are highly durable, making them difficult to tear or puncture. This sturdiness is beneficial during shipping, when packages encounter many stressors that would typically cause materials to break. For instance, many shipments travel in tractor-trailers, where they could be jostled around. Shrink wrap’s strong consistency keeps the items secure even during movement.

The durability of shrink film wrap also keeps it from weakening or sagging over time. After applying shrink wrap to an item, it stays tightly sealed, even when facing extreme temperatures or conditions. If your products travel long distances or through multiple distribution centers, this durability of LDPE will keep them protected and the product safe.

3. Versatility

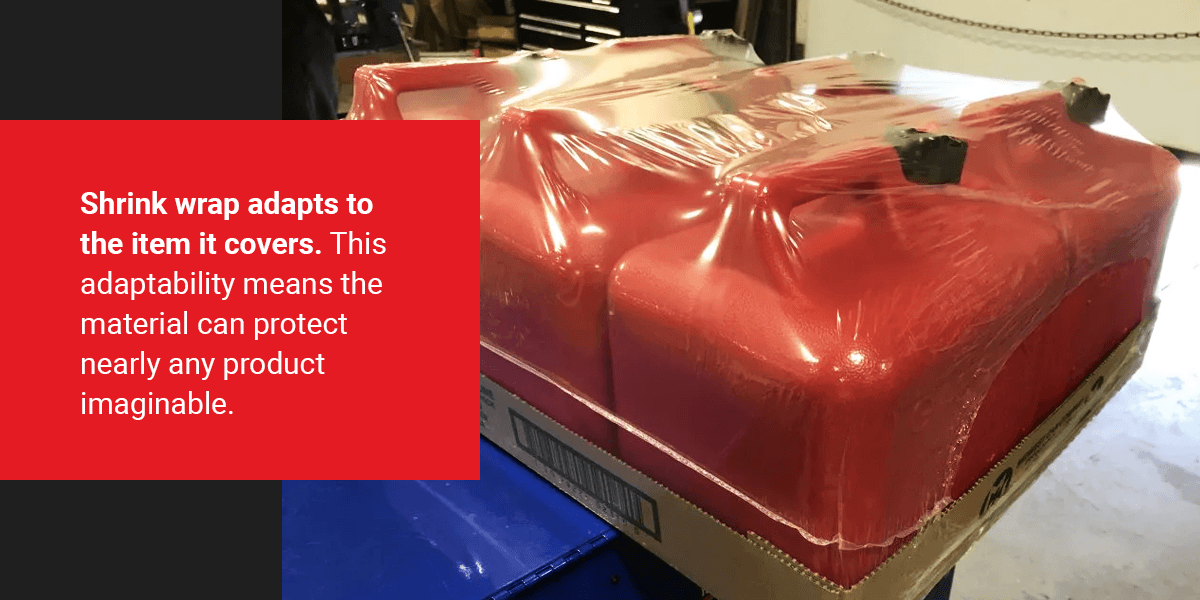

Another example of the advantages of shrink wrap packaging is its versatility. As mentioned before, shrink wrap adapts to the item it covers. This adaptability means the material can protect nearly any product imaginable.

Shrink wrap’s versatility extends to many industries, including:

- Cosmetics: Shrink wrap is also commonly used in the personal care and cosmetics market. The material wraps around individual products or groups them together for easier shipments.

- Food and beverages: LDPE shrink wrap bags is heavily used as a second packaging in the food and beverage industry as well as food containers such as drink carriers and Styrofoam plates.

- Travel: Many travelers choose to shrink wrap their luggage and other possessions during travel. This process keeps your bags airtight and safe from any outside contaminants.

- Medical and pharmaceutical: Hospitals and other healthcare organizations sometimes want their products delivered in shrink wrap to ensure they stay secure during shipping. Fragile medical products like laboratory bottles do well in secure packaging like LDPE.

- Pet materials: Shrink wrap is also used in the pet industry. Pet materials often come in cans or plastic packaging, and you can use shrink wrap to combine items. Other pet items like toys or sleeping products can be grouped with shrink wrap, as well.

- Construction: Shrink wrap is popular in the construction industry. Manufacturers can shrink wrap building materials such as roofing, windows, and rolls of insulation to keep them protected during delivery and at a construction site construction.

The versatility of shrink wrap makes it an ideal option, no matter your product type.

4. Water-Resistance

One of the most significant shrink wrap packaging benefits is its ability to deflect water. The wrap resists water for long periods, making transport through moisture-prone areas hassle-free.

If you encounter rain, snow, or something similar, your items will stay protected for significant durations underneath the shrink wrap. This is a crucial advantage for items that are sensitive to moisture, such as furniture. However, the plastic material LDPE allows water and oxygen to enter over time, so it shouldn’t wrap the items for too long.

5. Cost-Efficiency

In addition to these other benefits, shrink wrap packaging is a more cost-effective choice than many other packaging materials. You can use exact amounts of shrink wrap to enclose a product fully. This allows you to use less material than alternatives such as cardboard. The less material you use, the less money you have to spend.

Shrink wrap also takes up less space, meaning you can ship more products in the same shipment. You can fit more shrink-wrapped items onto trucks or warehouse shelves, saving you and other shipping professionals valuable space and money.

Many forms of shrink wrap are eligible for recycling. You can reuse these products or turn them into other materials, which saves both time and precious resources. In certain waste streams clean LDPE has a scarp material value and can be sold back to a film manufacturer.

EDL Packaging