Tubs/Bottles/Tottles

EDL has designed a system for you.

Whether it is 5 lbs tubs of peanut butter or 5 oz tubes of lotion

EDL provides a wide range of options in system styles and configurations to meet your tub and tube needs.

- Innovative collation and material handling options available for difficult to control products.

- Robotic pick and place options available for increased throughput.

- Constructed for 24/7 operations in any environment.

- Flexible packaging and bundling configurations.

- Both in-line and side-feed options available for space configuration optimization.

Flight Bar Automatic

Reduce film use, consume less energy and shrink bundle products with ease. Bundle and shrink wrap a wide variety of supported or unsupported products with this flexible solution.

EDL’s Flight Bar Automatic shrink wrapping machine provides the best combination of product handling and throughput rates. Common applications include light weight products or small multi-packs which require substantial handling throughout the wrapping process.

Automatic Flight Bar with Side Seal and Forming Shoe: Plastic Medical Bottles (SV145) (video)

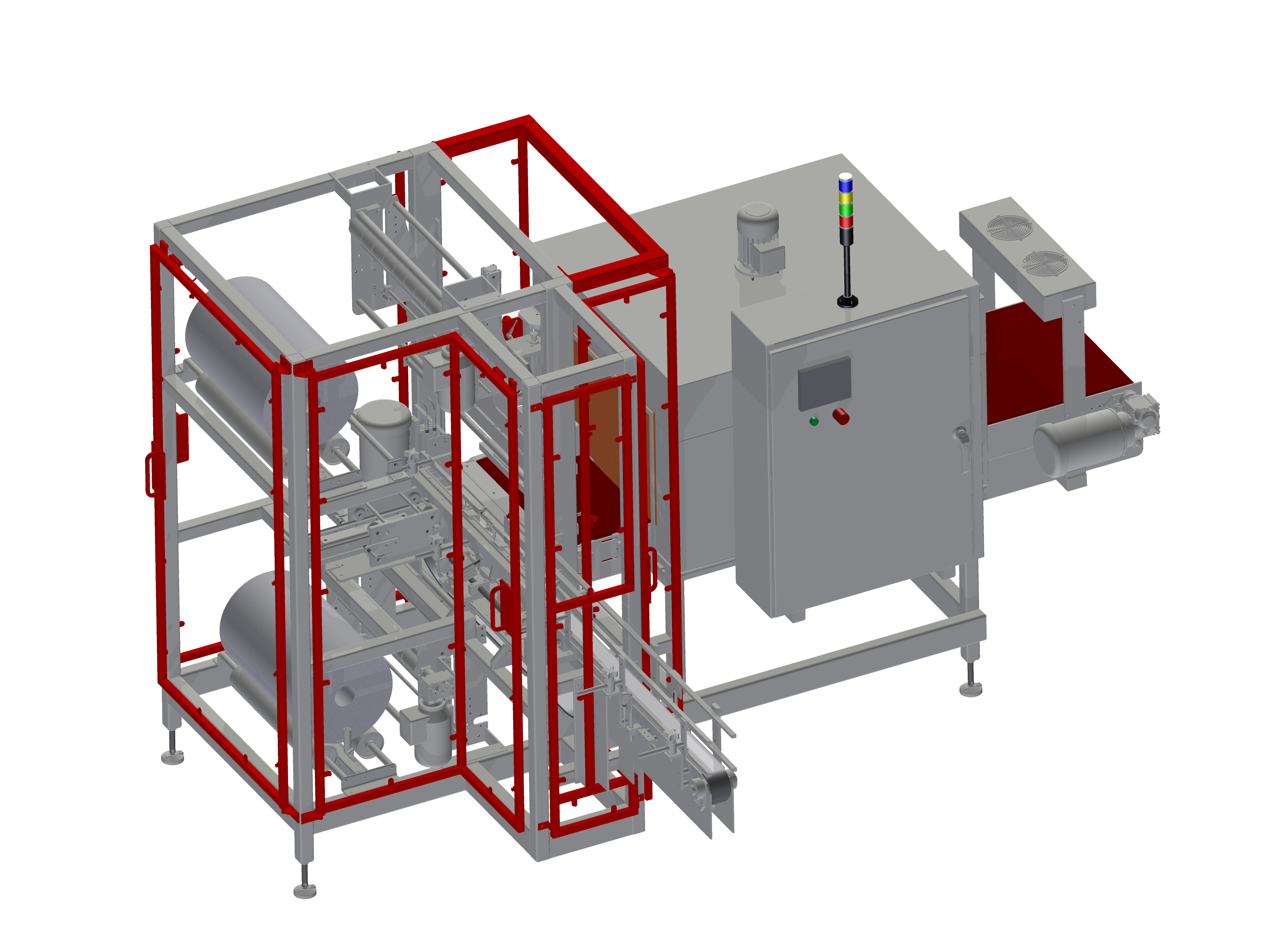

Side Feed Automatic

The versatile Side Feed Automatic shrink wrapping equipment is easily integrated into your existing production line. Turn, tier or invert collated products during infeed for correct orientation prior to wrapping.

EDL’s Side-Feed Automatic shrink wrapping equipment is designed to handle a wide variety of applications while providing a small footprint and flexible layout designs. This type of system is ideal for products that require collating or enter the system with the narrow edge leading. Multiple package enclosures are available.

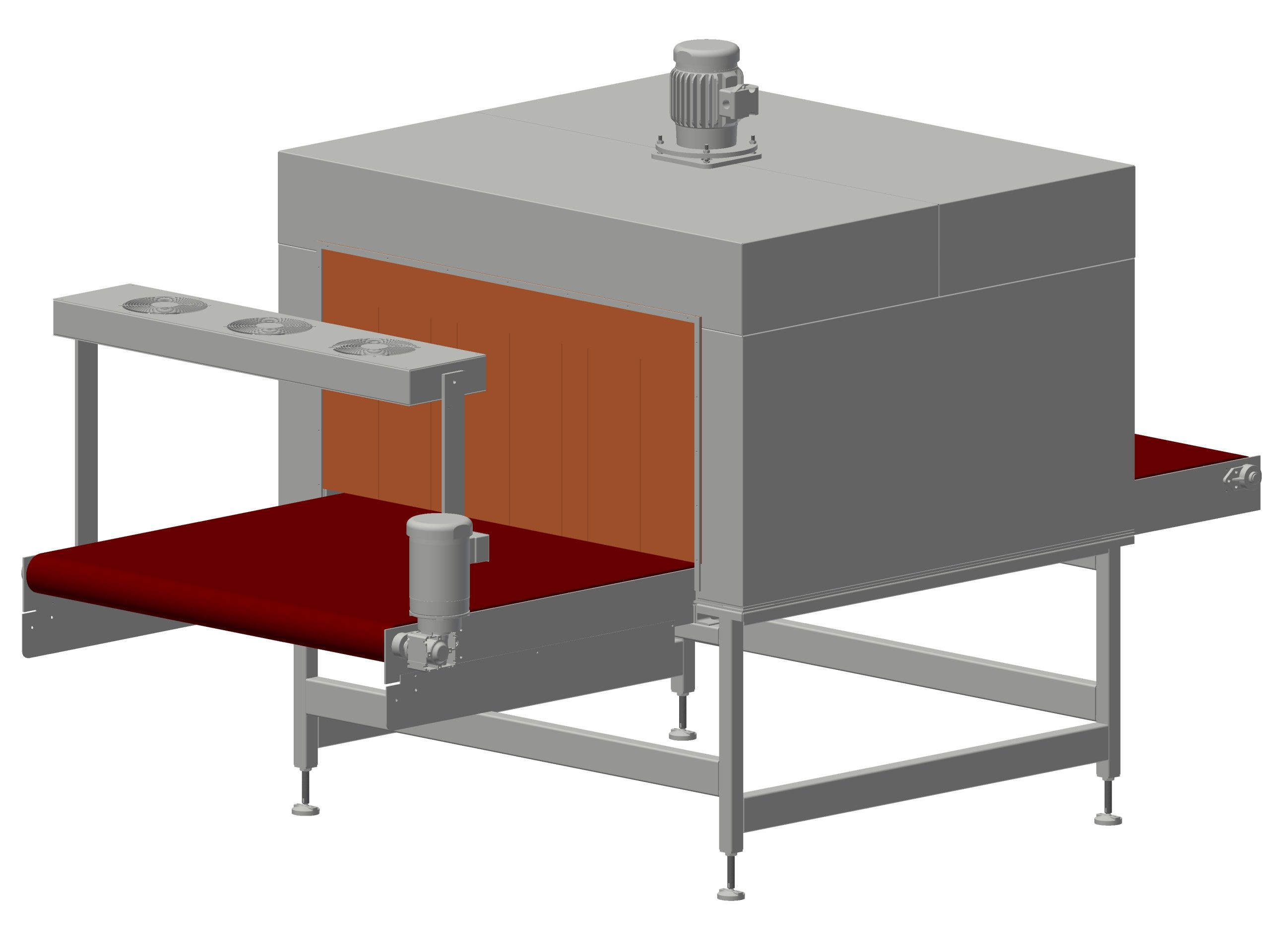

Shrink Tunnel

Heavy-duty, reliable and tailored to your product and package

Shrink tunnels are essential for achieving secure and professional packaging using shrink film. The heat applied in these tunnels causes the shrink film to tightly conform to product contours, ensuring long-lasting protection during transportation, storage, and display.

Our shrink tunnels, also known as heated shrink tunnels or shrink wrap tunnels, feature a high temperature-rated Habasit conveyor belt and a dual-shell hood design with ceramic fiber insulation for efficient heat retention. They include a direct drive overhead hot air blower and silicone entrance and exit curtains for precise heat distribution. Film cooling fans at the exit ensure a smooth finish.

- High temperature rated Habasit conveyor belt

- Dual shell tunnel hood design

- Ceramic fiber insulation between exterior and interior hood shells

- Ceramic fiber mat insulation between hood assembly and tunnel frame

- Direct drive overhead hot air recirculation blower

- Silicone tunnel entrance and exit curtains

- Film cooling fans at exit

Contact us to learn more about the shrink tunnel machine.

The EDL Packaging Engineers Guarantee

- Performance Guarantee ensures EDL machines will perform as specified. All machines are thoroughly tested to the highest standards

- Equipment Warranty provides a full two-year warranty on parts (equipment warranty excludes consumables)