Double Tight Wrap

Double Tight Wrap Shrink Wrapping Machines: Get unitization, stability, protection, and product visibility.

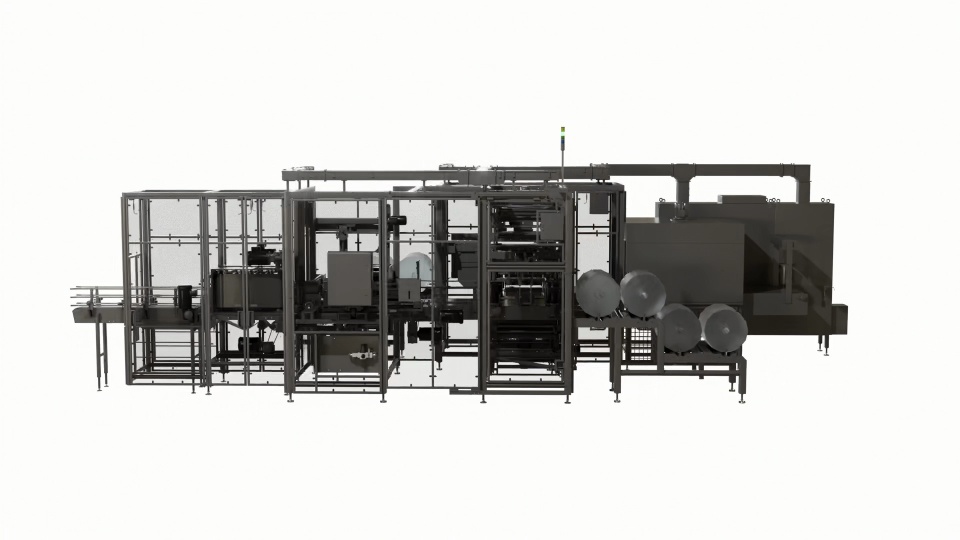

EDL’s Double Tight Wrap Shrink Wrapping machine is the packaging industry’s gold standard in tight wrap technology.

EDL Double Tight Wrap shrink wrapping machines use two perpendicular bands of LDPE film to tightly unitize and totally enclose a product or collation. Common applications include gable-topped bagged and pouch products and cube-shaped products requiring total enclosure. Markets have benefited include pet food, food service consumables, and food.