Food – Tray/Pad Supported

Trayed product solutions keep things moving.

Automatically accumulate, collate, place and wrap products. Tray Shrink Packaging Style Options:

Trays – corrugated, chip board, wrap-around, pre-formed, single or multiple stacks, vac-formed with pick and place

- Low, medium or full height trays

- Enables product and package graphics to be displayed

Pads – corrugated

- Minimal material cost while providing a stable base

- Prevents can rim wear

U-Board – corrugated

- Reduced material costs

- Increased stack and pack strength

- Billboard for unit graphics

- Ideal for products that cannot support their own weight

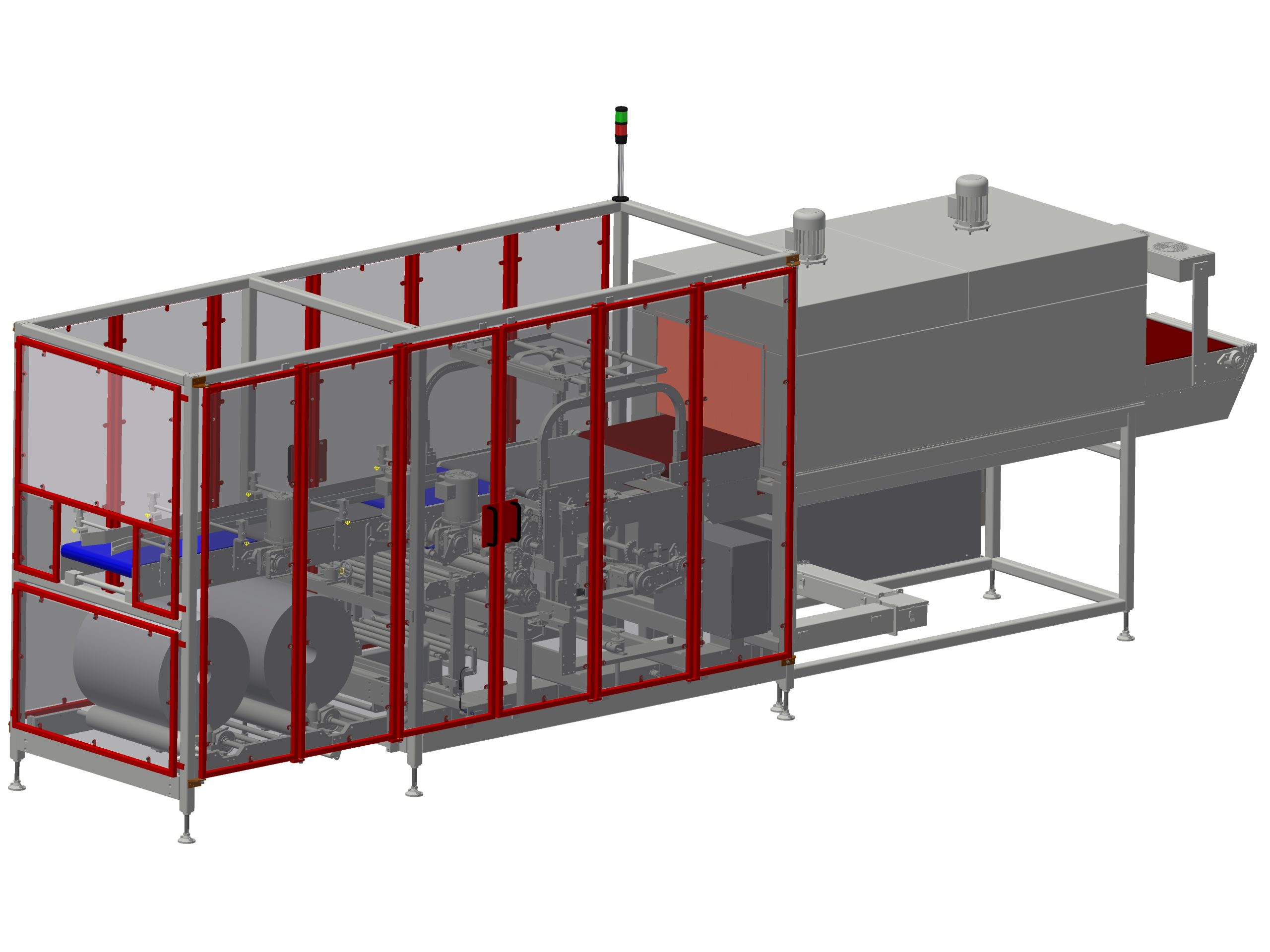

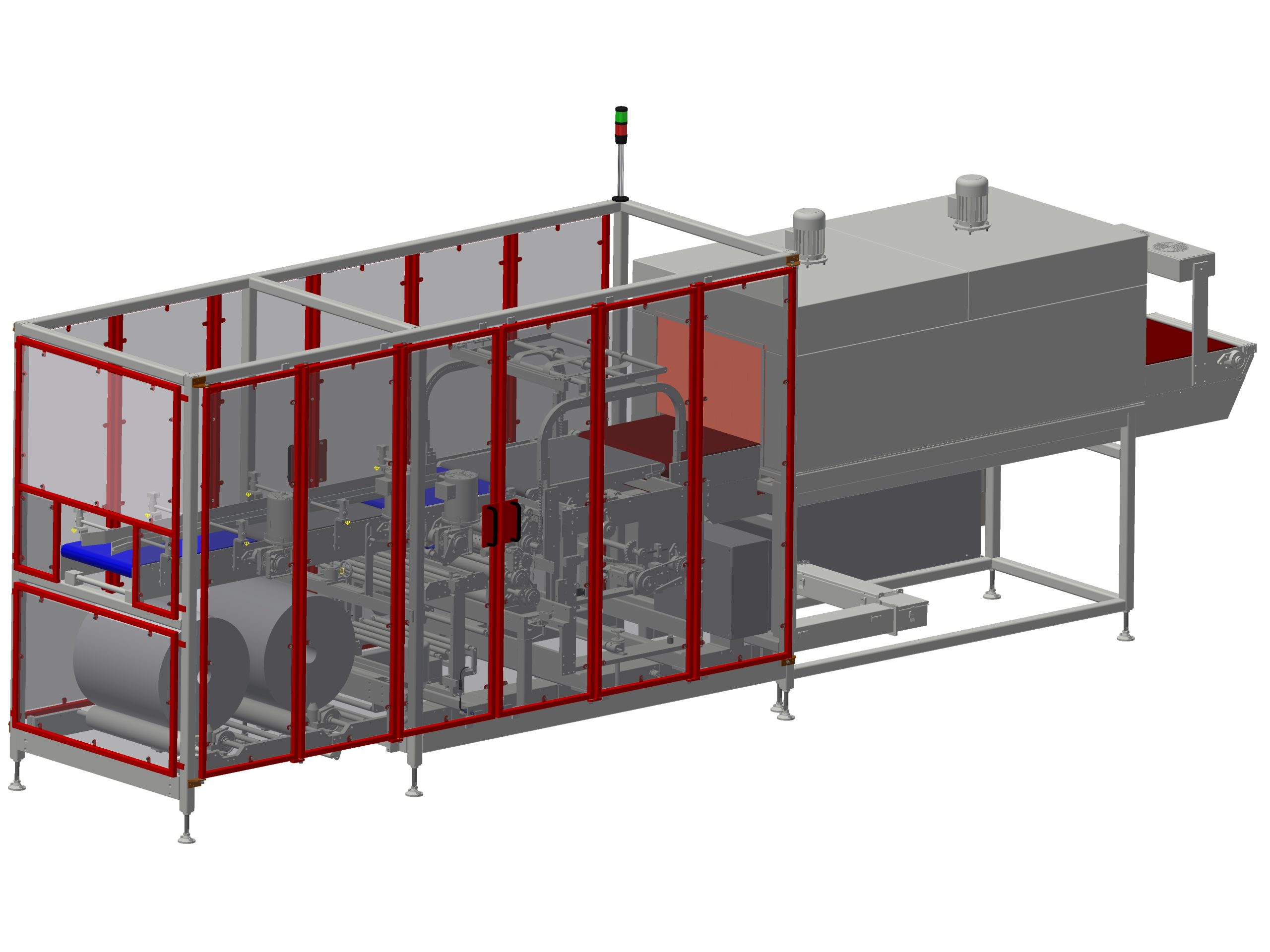

Continuous Motion Inline Automatic Wrap

EDL’s Continuous Motion Wrapper handles many supported and unsupported products. Wrap random sized packs when using the same film width and enjoy optional automatic film splicing.

EDL’s Continuous Motion Inline Automatic wrap systems are a faster, modified version of the base inline automatic system. The servo controlled, continuous-motion seal jaw moves with the product during the seal process for increased line speeds. Continuous motion inline automatic wrap systems can be designed to handle a wide range of applications, and is capable of wrapping up to 35 packs per minute.

EDL has experience manufacturing tailored secondary and end-of-line packaging machines for the automotive industry.

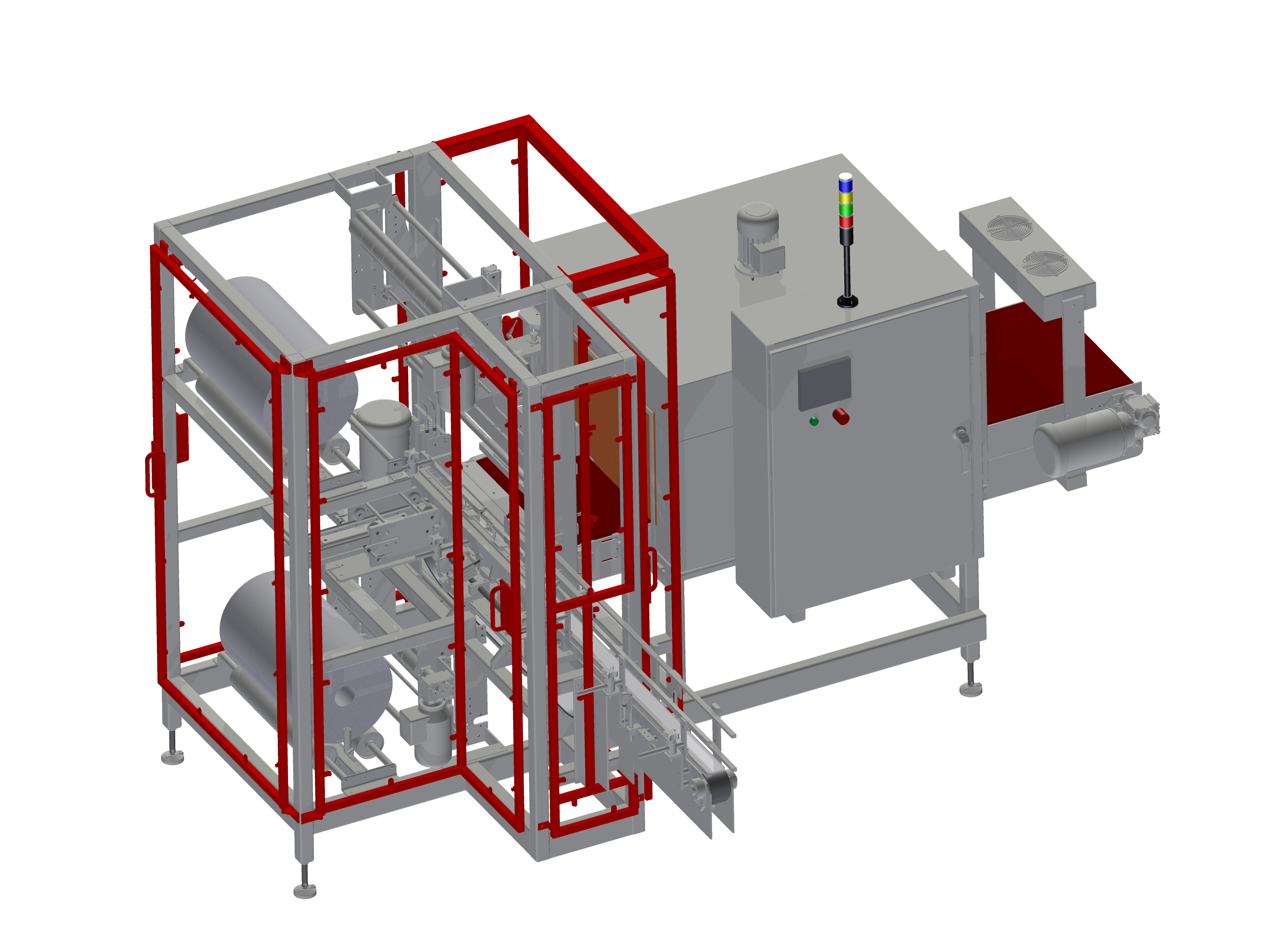

Flight Bar Automatic

Reduce film use, consume less energy and shrink bundle products with ease. Bundle and shrink wrap a wide variety of supported or unsupported products with this flexible solution.

EDL’s Flight Bar Automatic shrink wrapping machine provides the best combination of product handling and throughput rates. Common applications include light weight products or small multi-packs which require substantial handling throughout the wrapping process.

Automatic Flight Bar with Side Seal and Forming Shoe: Plastic Medical Bottles (SV145) (video)

Inline Automatic Shrink Wrap Machine

Maximize your speed and efficiency, while maintaining package quality. Experience an Inline Automatic Shrink Wrap Machine.

Inline Automatic Shrink Wrap machines are EDL’s most flexible secondary packaging solution. These systems are designed to shrink-wrap a variety of products, including bundling and shrink-wrapping cartons to shrink-wrapping large windows in multiple package enclosures at low to moderate speeds.

What’s the Difference Between Inline Automatic and Continuous Motion Systems?

Semi-Automatic Wrapper

Semi-Automatic Wrapper handles trayed, trayless or padded products. When high quality packs are required but full automation is secondary.

The Semi-Automatic Wrapper (Monobloc Semi-Automatic) is a cost-efficient,secondary or end-of-line packaging solution for a wide range of applications. It is designed for reduced throughput rates and requires operator loading of product and activation of each wrapping sequence. This versatile system can be quickly and easily integrated into existing production lines.

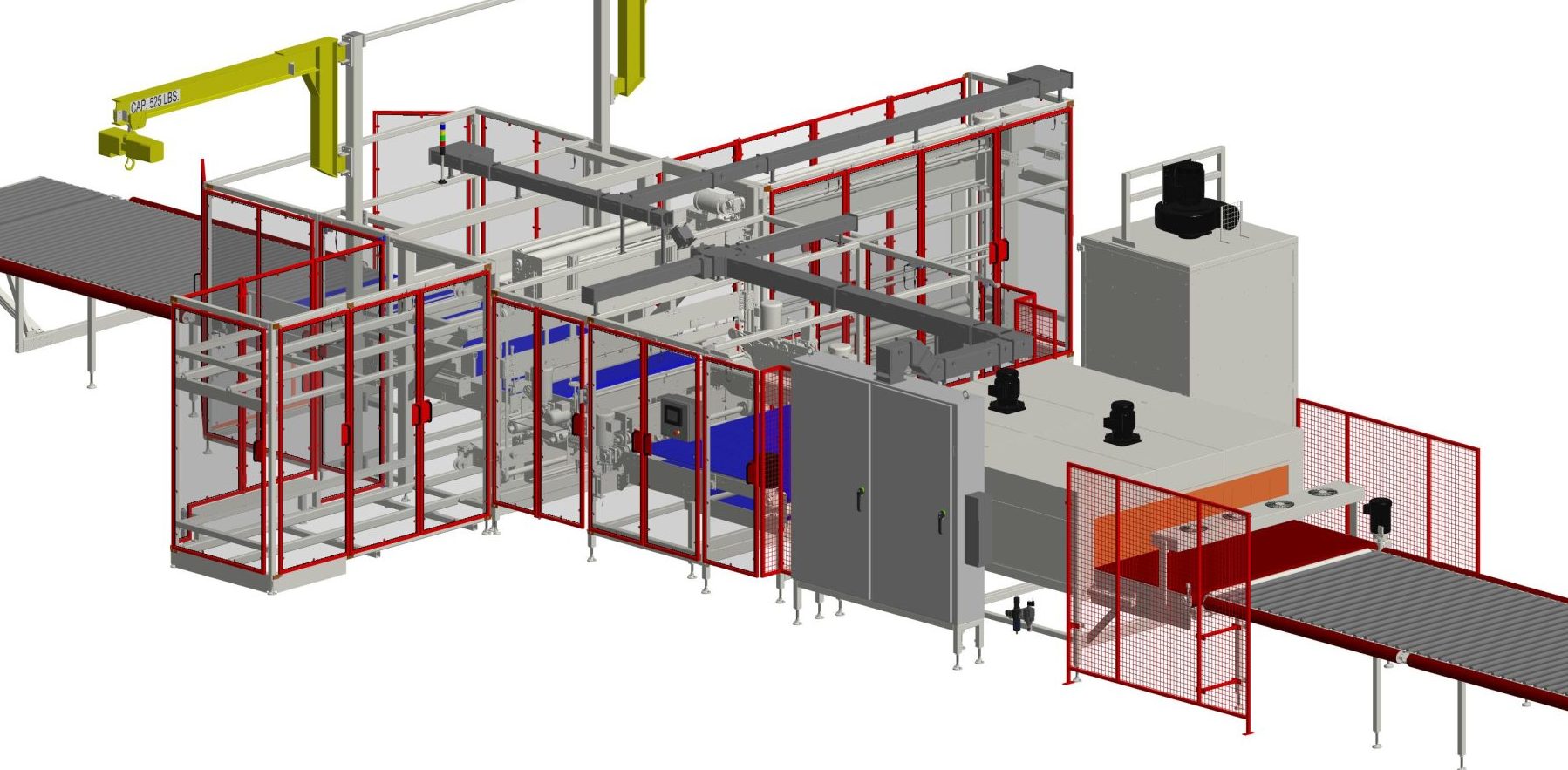

Side Feed Automatic

The versatile Side Feed Automatic shrink wrapping equipment is easily integrated into your existing production line. Turn, tier or invert collated products during infeed for correct orientation prior to wrapping.

EDL’s Side-Feed Automatic shrink wrapping equipment is designed to handle a wide variety of applications while providing a small footprint and flexible layout designs. This type of system is ideal for products that require collating or enter the system with the narrow edge leading. Multiple package enclosures are available.

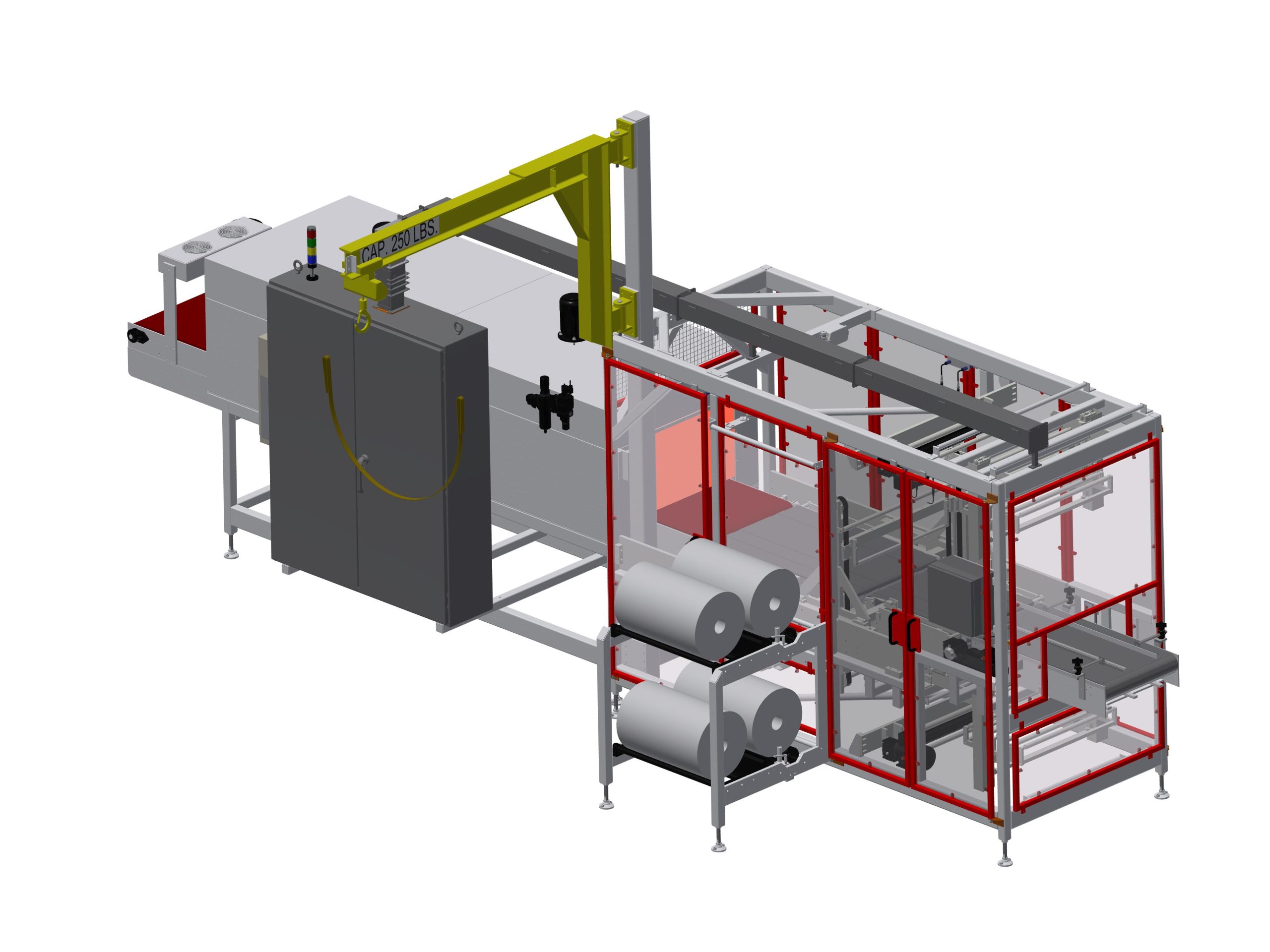

Single Roll Wrapper

Fast, efficient throughput: Single Roll Wrappers offer the highest throughput for trayed and trayless applications.

EDL’s single roll wrapping systems offer our highest throughput rates typically from 20 -45 packs per minute. Common applications include trays of food or beverage product and collations of containers. The single roll wrapping system is based on an inline layout and can be easily integrated into an EDL up stream wrap around tray former. EDL single roll wrappers can run clear and print registered film.

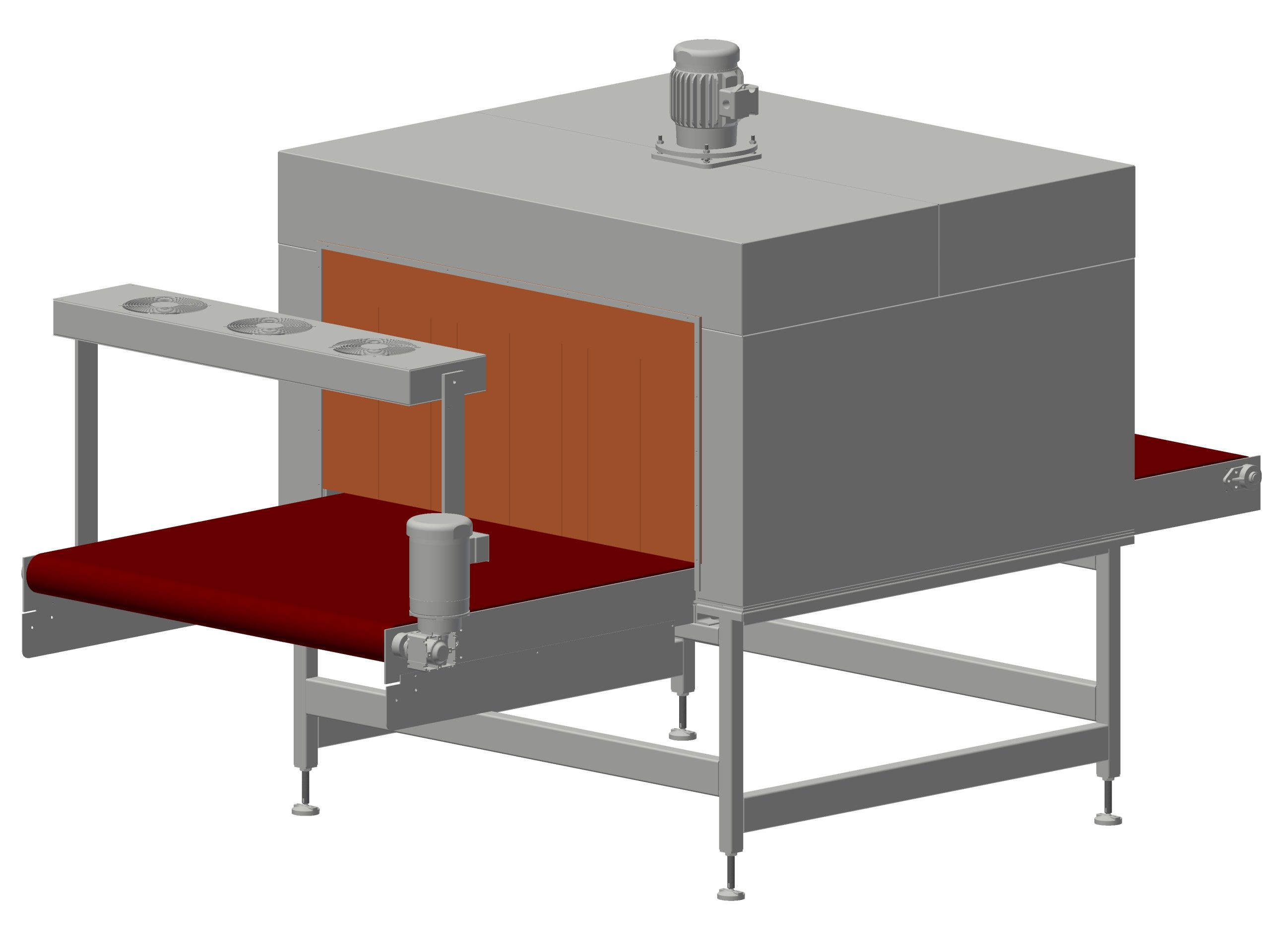

Shrink Tunnel

Heavy-duty, reliable and tailored to your product and package

- High temperature rated Habasit conveyor belt

- Dual shell tunnel hood design

- Ceramic fiber insulation between exterior and interior hood shells

- Ceramic fiber mat insulation between hood assembly and tunnel frame

- Direct drive overhead hot air recirculation blower

- Silicone tunnel entrance and exit curtains

- Film cooling fans at exit

Contact us to learn more about the shrink tunnel machine.

Tray Wrappers

The perfect combination of capability and flexible for your tray wrapping needs

EDL offers a comprehensive lineup of tray wrapping equipment, starting with the Single Roll Wrapper which accommodates up to 50 packs per minute and print registration. Other tray wrapping systems options include a continuous motion inline wrapper, flight bar wrapper and inline automatic wrapper.

EDL also can provide a Wrap-a-round Tray Former in front of the wrapping system, complete with product collator and single lane or flood feed options. The Wrap-a-round Tray Former will be integrated into the wrapping system to create a ‘single machine’.

Watch our videos to learn more!

Tray Shrink Packaging Features and Benefits

- Enables unstable products to be packaged with support and protection

- Unitize and protect with a chipboard or corrugated board on 1.25 to 3 mil polyethylene film (depending on application)

- Reduce or eliminate costly corrugated packaging

- Enhances the product with optional random printed or print registered film

- Engineered to satisfy the highest performance and productivity standards

- U-board and tray provides billboard display opportunities

- Random printed or print registered film can be utilized to display graphics

- Film perforation units for easy-open packs, allows pack to remain intact after partial content removal

- Product stacking or tiering options available

Trayless Shrink Packaging Style Options

- Random printed or print registered film can be utilized to display graphics

- Film perforation units for easy-open packs, enables pack to remain in tact after partial content removal

- Pack-dividing film perforations enable larger packs to be broken down into smaller packs

- Product stacking or tiering options are available

Features and Benefits

- Eliminates costly corrugated or chip board packaging

- Designed and engineered to use minimal material and energy

- Systems are designed with the customer’s requirements in mind and are custom engineered

- Enables unstable products to be packaged without a tray or pad

- Custom engineered to meet product requirements

- Unitizes and protects the product with 1.25-3 mil polyethylene film (depending on application)

- Enhances the product with optional random printed or print registered film

- Clear, tinted or printed polyethylene film

- Full range of closures: total, partial, tuck and fold

The EDL Packaging Engineers Guarantee

- Performance Guarantee ensures EDL machines will perform as specified. All machines are thoroughly tested to the highest standards

- Equipment Warranty provides a full two-year warranty on parts (equipment warranty excludes consumables)