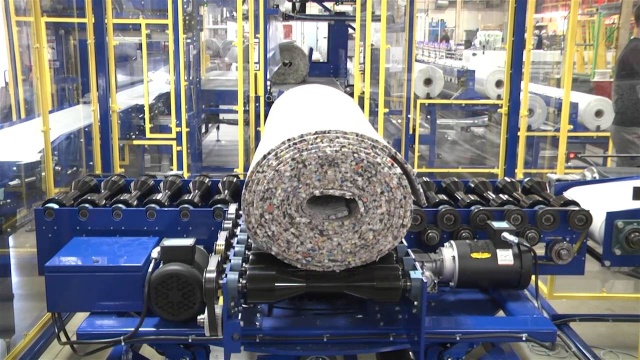

Roll Wrapper

Package and protect your rolled products.

Roll Wrapper solutions for carpet, vinyl flooring, fabric, textiles, rubber, felt, and more. EDL’s roll wrapping systems are designed to wrap rolled products. Common applications include carpeting, foam padding, textiles and rolled building materials. The side feed layout of the roll wrapper allows for easy integration of additional modules for further system capabilities.